Applications I

Bridges, Barriers walls and decks

Traditional Steel reinforced concrete infrastructure projects have shorter service life and higher repair costs as compared to non-metallic concrete reinforced solutions.

BENEFITS OF FRP REBAR

- Lightweight

- 1/4 the Weight vs. Steel Rebar

- Non-Corrosive and Unsusceptible to Chemical spills

- Safer to install

- Long-term durability

Applications II

Pavements, multi-storey parking garages, roads and balconies

Deterioration is usually caused by corrosion of the reinforced Steel in the harsh environment of multi-storey parking garages structures. Pavement and balconies exposed to open-air face the same issues.

BENEFITS OF FRP REBAR

- Corrosion resistant

- Shorter time during installation and construction of the building

- Competitive cost and energy efficiency

Applications III

Diaphragm walls (soft eye) and foundation pit retaining piles

Tunnel Boring Machines (TBM) are widely used in tunnel projects, but TBMs are not well suited to work their way through Steel reinforced concrete structures, because of the resilience of the Steel. Steel ductility will seriously hinder the work of the rotary cutters by absorbing the cutter’s energy.

BENEFITS OF FRP REBAR

- GFRP reinforced concrete launch box is a better option

- Cuttability

- Permanent application

- 1/4 the Weight vs. Steel Rebar

- Long-term durability

- High end loading

- Flexibility

- Non-Corrosive and Unsusceptible to Chemical spills

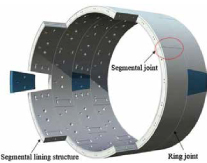

Applications IV

Precast Tunnel Segments

The use of Steel rebar as structural reinforcement in precast tunnel segments has several disadvantages in terms of low structural durability and high weight of segment for transportation. Furthermore, this reinforcement type can create electric joints, which often lead to corrosion problems.

BENEFITS OF FRP REBAR

- Demolished later

- Temporary Application

- Permanent application

- Flexibility

- 1/4 the Weight vs. Steel Rebar

- Non-Corrosive with dielectric joints

- Long-term structural durability

Applications V

Mining roadway support and tunnels with Rock bolts

Steel bolts are harder to cut by mining machines and can cause fires and explosions in gas/coal mines. For tunnel projects in particularly corrosive environments, traditional Steel rebar for concrete reinforced solution structures have bad durability, such as in underground or in deep sea ground.

BENEFITS OF FRP REBAR

- Easily cut by mining machines

- Antistatic and Explosion proof

- High tensile strength

- Light weight and improves installation work efficiency

- Corrosion resistant

Applications VI

Wharfs, sea walls, wave breakers and water treatment plants

The deterioration of reinforced concrete structures in marine or chemical water projects, usually affected by the migration of chloride ions that in turn leads to the corrosion of the Steel rebar of the structures, is a very serious problem of worldwide proportions.

BENEFITS OF FRP REBAR

- Totally unaffected by chloride ions

- High tensile strength the best option in marine environment installations

- Long-term durability

- High tensile strength

- Easy handling