FRP (Fiberglass Reinforced Polymer) is a composite material made of a polymer matrix reinforced with fibers. The fibers are usually glass (in fiberglass), basalt, carbon, or aramid. The polymer is usually an epoxy, vinyl ester, or polyester thermosetting plastic.

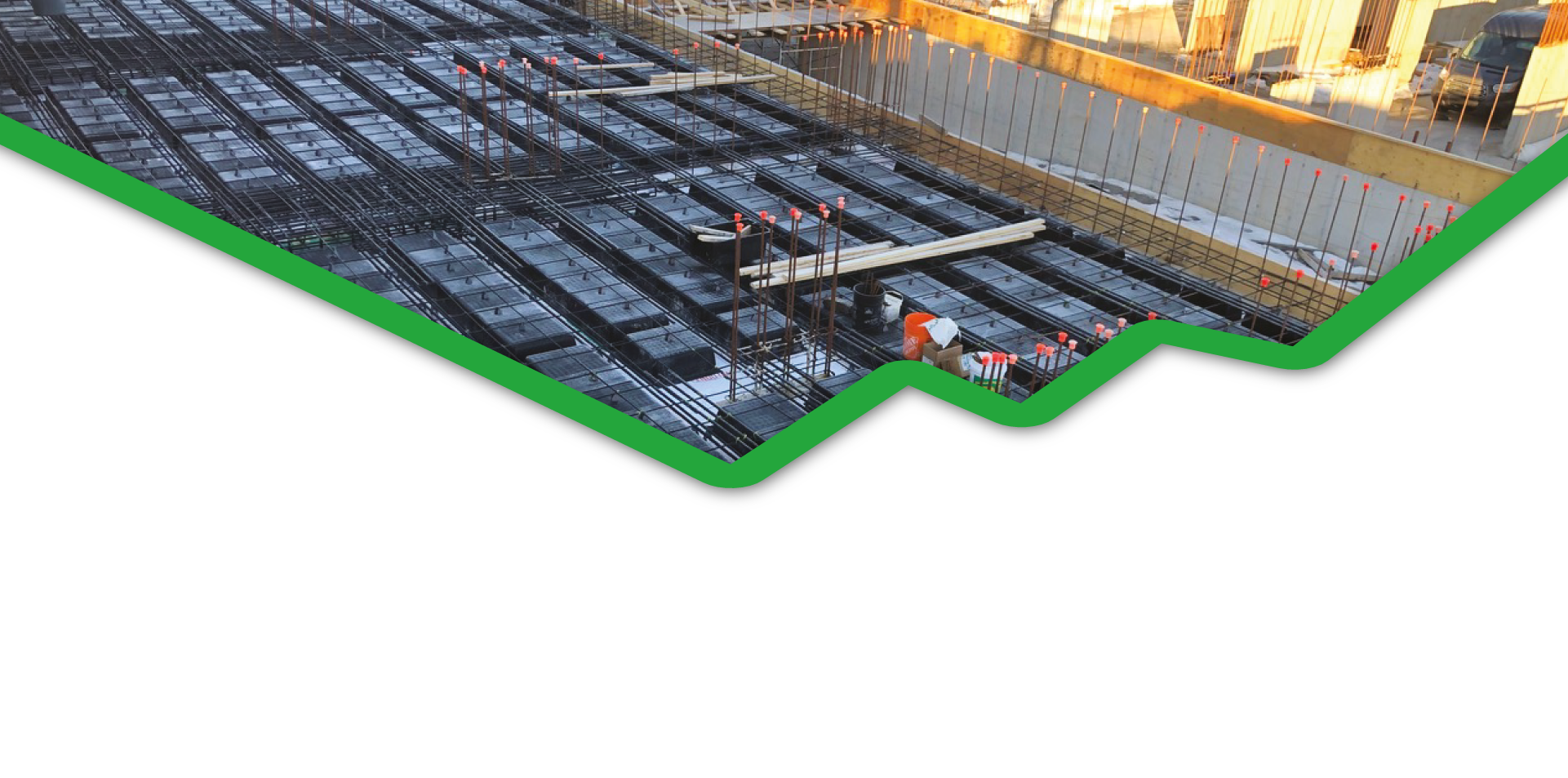

FRP bar has been developed as a non-corrosive alternative to steel for concrete reinforcement.

FRP bar is suitable for any structural or architectural application where a material that is corrosion resistant, lightweight, or non-conductive is required.

• Tensile Strength is Greater than Steel

• Electrically and thermally non-conductive

• Transparent to Magnetic Fields & Radar Frequencies

• Extremely Lightweight – 75% Lighter than Steel Rebar

• Will Never Corrode – Conservative Estimates Indicate Longevity Over 100 Years

Use our estimator tool to find out

how much you can save on your next project.

| SFT-Bar® | Steel | |

| Production | 43% less CO2 Emissions | High CO2 Emissions |

| Transport | Fewer construction freight | High construction freight |

| Service Life | Long (resistance to corrosion) | Short due to corrosion |

The following new reports EER-5081 & ESR-5081 have been published on the ICC-ES® website (http://www.icc-es.org). The ESR-5081 and EER-5081 reports certify the SFTec Inc. SFT-Bar® and also attest to its compliance to the most advanced and stringent requirements, codes and standards applicable in construction, that codify the use of GFRP in concrete structures).

ICC-ES® is the leading evaluation service for innovative building materials, components and systems. ICC-ES® Evaluation Reports (ESRs), Building Product Listings and PMG Listings provide evidence that products and systems meet requirements of codes and technical standards worldwide, including the US, Canada, Mexico, Australia, New Zealand, and the MENA region. ICC-ES® is a member of the ICC family of solutions.

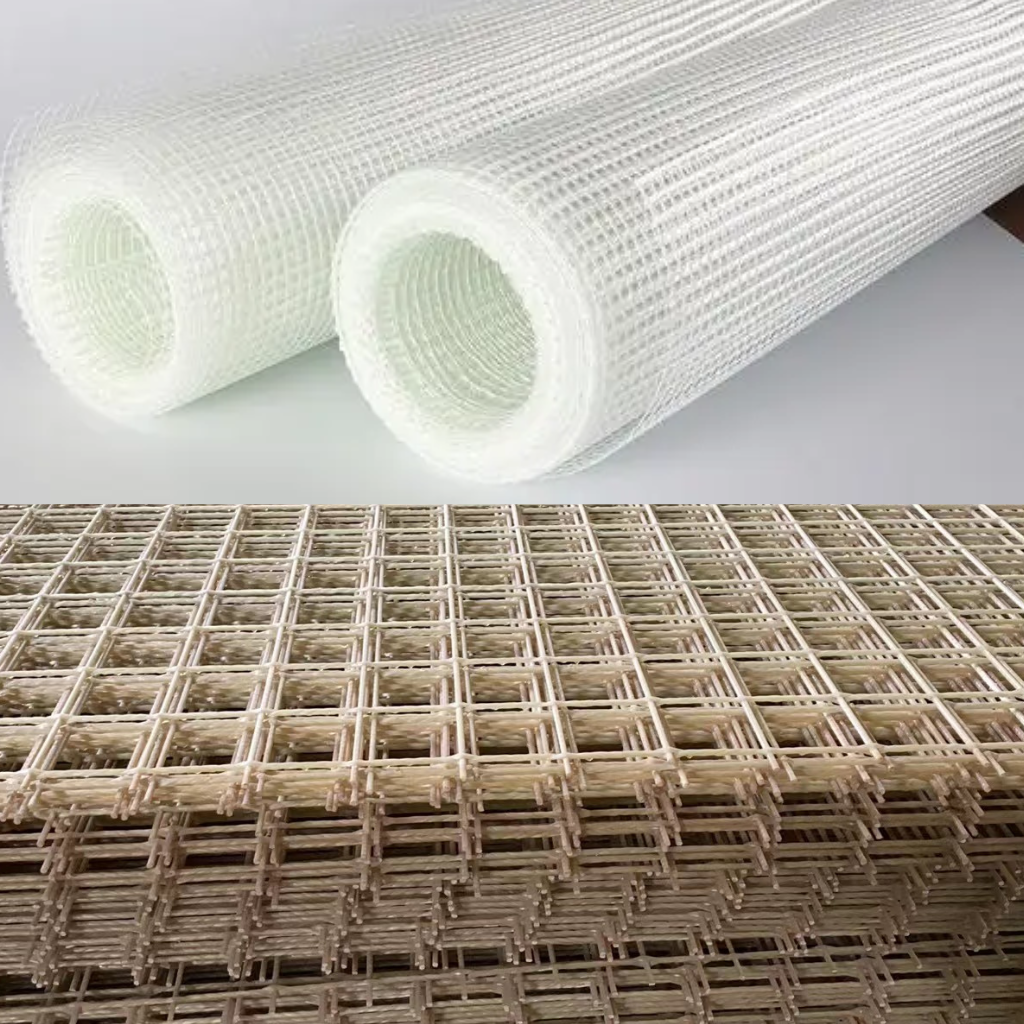

Alkali Resistant Glass Fibers designed and manufactured to easily be incorporated into concrete mixes. Their properties allow them to reduce/prevent cracks in concrete structures with a longer durability compared to steel.

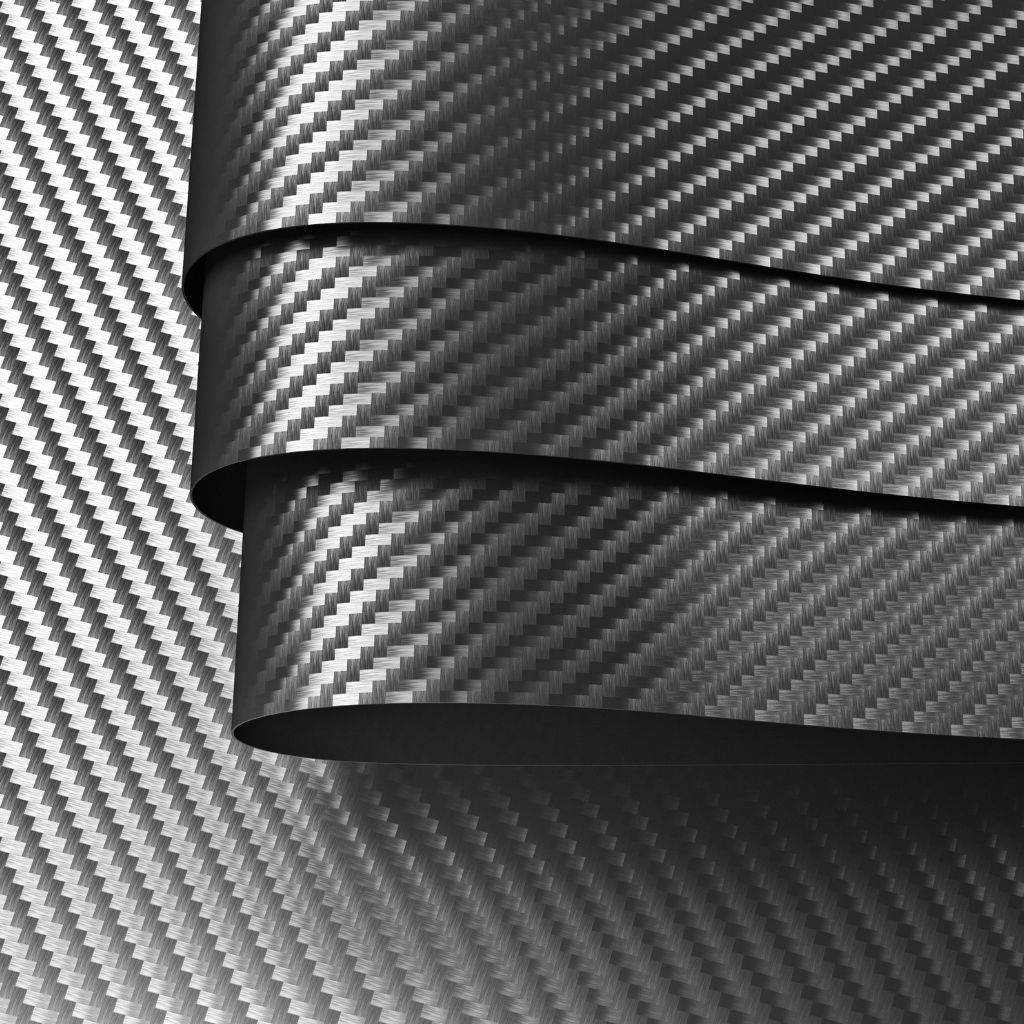

Easily applied with Epoxy adhesive, these light, durable and resistant Carbon straps are ideal to fill crack and eliminate infiltrations. Other applications include reinforcing a concrete structure, increasing its load capacity, or repairs.

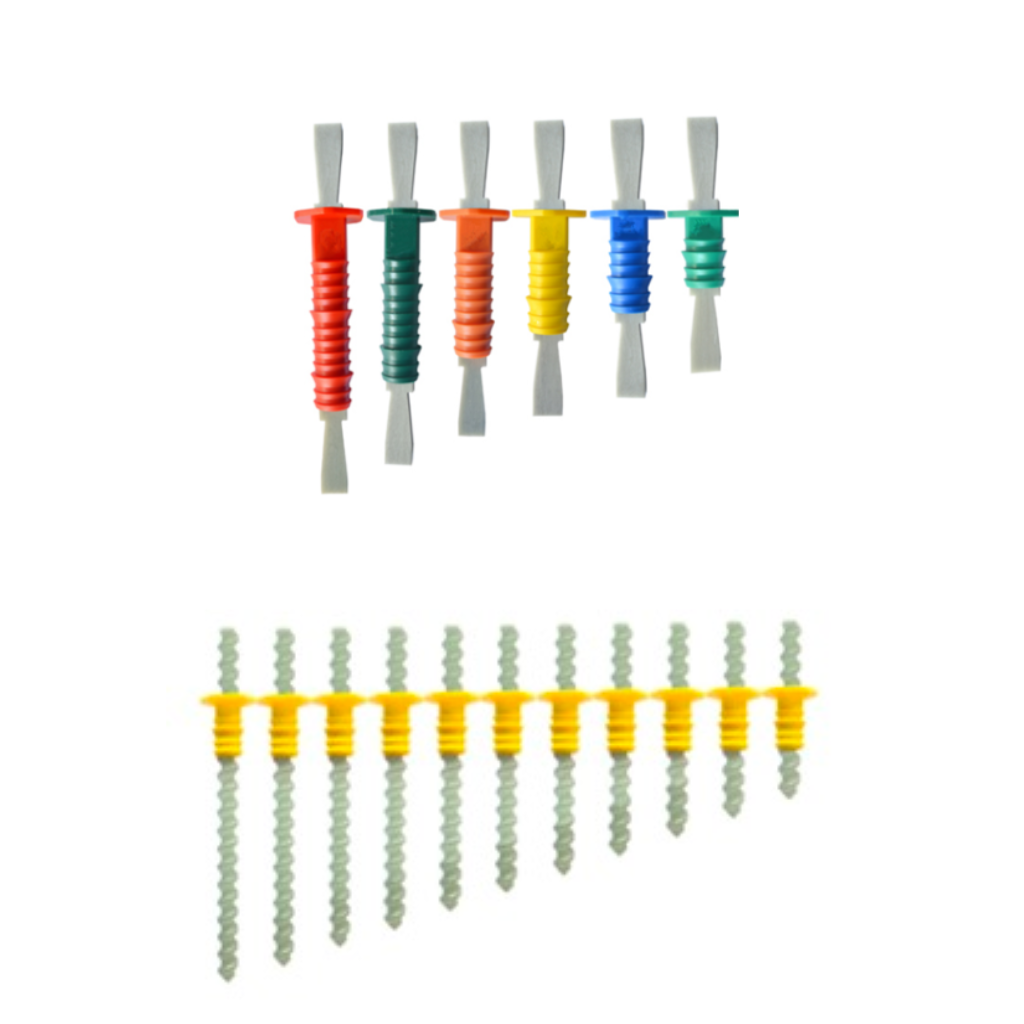

Evaluated on various criteria such as color, type, tensile strength, compression strength, tensile modulus and shear strength, find the type that fits best your project needs or contact us so we can make the best recommendation for your requirements.

For Structure Strengthening

For External Surface of Walls

SFT-TwistedBundleFiber have many advantages thanks to their unique properties. In addition to preventing further expansion of concrete structures and helping maintain the structure integrity, this material can prevent cracks.

If you would like to purchase our products in small quantities, visit our retail page.

Register to our newsletter to stay up to date and be the first to get access to our resources.

Email address

© 2021 – SFTec Inc. – All Rights Reserved

Register to our newsletter to stay up to date and be the first to get access to our resources.

Email address